Front wheel kit 500W to 750W without battery for CARGO and TANDEM bikes

80N.m torque for this front wheel motor kit designed for cargo bikes and riders over 90kg. Powerful front wheel motor and reinforced rim

but also waterproof connectors and thermic protection.

Contenu de ce pack:

DONKEY Motor Quantité : 1 269,00 € |

wheelbuilding on French Mach1 double wall rim with 2.3 mm stainless steel spokes |

Displays selection for wheel motor 250W to 750W |

22A 36V and 48V external controller FOC for OZO hub motors 500W and 750W |

Pedal sensor adapted to your bike |

Main wiring harness for 15A and 22A OZO controller |

Torque arm adapted to your bike Quantité : 2 50,00 € |

Rallonge moteur 9 PINS 110cm |

3 pins Julet Bafang cable extender Quantité : 1 14,50 € |

Extension cable Julet for bafang display 5 pins or OZO display Quantité : 1 18,00 € |

Mounting pack for electric kit Quantité : 1 Gratuit |

ADVANTAGES OF THE 500W-750W FRONT WHEEL MOTOR

The motor delivers a maximum torque of 80N.m powered by a 48V battery.

This version is recommended for medium-weight cargo bikes, folding bikes, or tandem bikes with a rider weighing between 80kg and 90kg.

KIT CONTENTS

THE DONKEY MOTOR

| The "Donkey" motor is a reduced motor with reinforced epicyclic gear and internal freewheel. This allows you to have a lot of torque and a great facility with the pedalling since the engine is completely disengaged when it is not fed... You pedal like on a traditional bike without the motor braking you. The "Donkey" motor is supplied with washers that will allow you to center the wheel in your frame. It can be installed on all traditional frames equipped with a front axle in 100mm of center distance. You will be able to screw your brake disc to the standard 6 holes on the motor. For bikes equipped with brake pads, don't forget to order a rim with surfaced edges like the Kargo. |  |

| With your kit you receive a complete drive wheel. All our wheels are carefully spoked in our workshop by enthusiasts: spoke tension, centering, sail and false round, everything is checked before shipping. The 36 spokes are made of stainless steel 2,3mm diameter, made in France. These French made rims will allow you to use your kit in all conditions. For bikes equipped with brake pads, choose a rim with surfaced edges like the Mach1 Kargo. |

THE 22A CONTROLLER AND ITS BEAM

| The 22A controller comes with a fully sealed Julet connector that is very easy to install. Each connector has a coding device, so there is no risk of making a mistake. |

A single cable runs from the motor to the handlebars to connect the various accessories: 2 Red connectors for the brake cutters 1 Green connector for the handlebar display 1 Yellow connector for the gas pedal (optional) |

|

THREE CONTROL SCREENS TO CHOOSE FROM (DISPLAY)

THE PEDAL SENSOR

On the wheel motor kits that are equipped with 15A controllers and more, you will need a pedal sensor. This will engage the motor and therefore the assistance of the bike. The pedal sensor is a rotation sensor. You are obliged to pedal to have the assistance. There are several types of sensors to match 90% of bikes on the market. Integrated bottom bracket sensor: For square axle bottom brackets that have a minimum clearance of 4mm between the crank and the frame. Bottom bracket sensor with magnetic disc: For all other bikes that do not have the minimum clearance to install an integrated sensor. |  |

THE TORQUE ARM

| The torque arm is a laser-cut stainless steel part that prevents the drive wheel nuts from loosening so as not to damage the frame of your bike. The torque arm is essential with the Donkey kit. To choose the right model for your bike, please read the instructions on the role of the torque arm. |

OPTIONAL ACCESSORIES

|  |

The throttle offers the ability to control the motor without pedaling. In the form of a thumb trigger, the throttle can be installed on the right or left side of the handlebars. Note, however, that the throttle is not approved for use on roads open to traffic. It can be used on a mountain bike to help with hill starts and obstacle crossing. | The brake cut-off is an additional safety feature that cuts off power to the motor when braking. This is particularly useful during delicate maneuvers. The brake cut-off comes in different forms: Brake handles that can be installed in place of your original handles. The sensor on cable which is installed on the brake cable. The magnetic sensor to be reserved for bikes equipped with hydraulic brakes. |

| |

OZO has selected for you the best tires for 20-inch front ATVs on the market. With integrated anti-puncture protection or double ply, you will find all the tires in the tires section |

ON WHICH BIKE CAN I INSTALL A 500W to 750W FRONT WHEEL MOTOR?

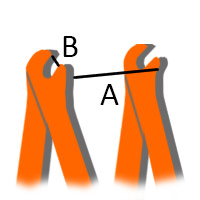

The 500W to 750W front wheel kit is compatible with all bikes equipped with a 9x100mm or 10x100mm front wheel axis. To be sure that the installation is possible on your bike, you need to check that you have a traditional open frame with 100mm center distance. With a ruler, measure the inside width of your frame (value A). You must have at least 100mm (10cm). Then measure the frame notches (B value). You should have 9 or 10mm. |  |