HOW DOES A WHEEL MOTOR WORK?

Today the wheel motor, also called the hub motor, has become a simple and essential means of electrifying a large number of light vehicles (bicycles, motorcycles, scooters, scooters, etc.). In fact, this solution, fixed directly to the frame, does not require the readjustment of the transmission. This is a "brushless" motor, that is to say brushless motors.

There are 2 types of wheel motors: the direct drive motor and the so-called reduction motor.

In this article, we will focus on these 2 engines, different in their design, each of which has interesting advantages but which can also present some disadvantages for certain types of use.

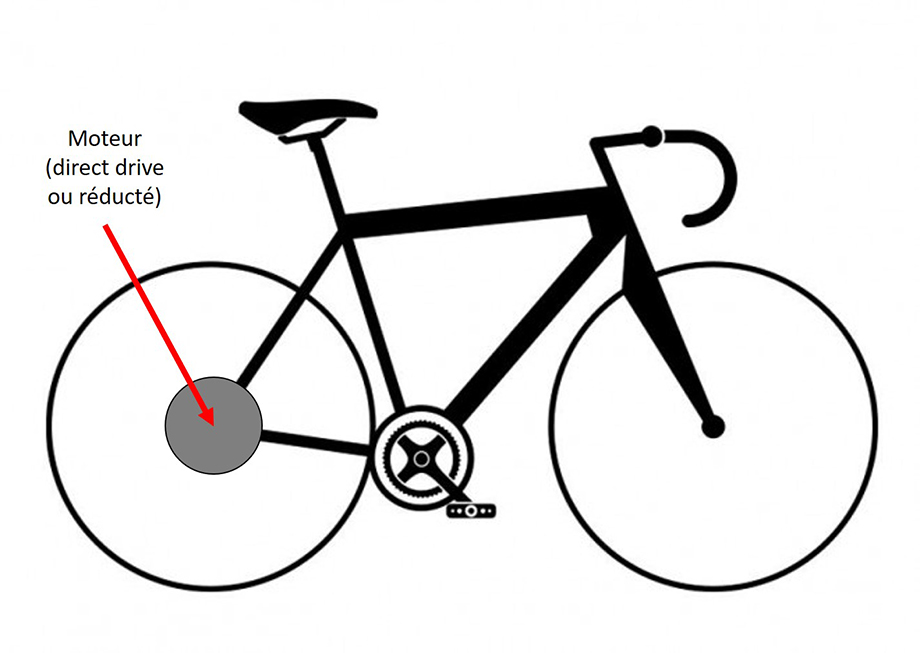

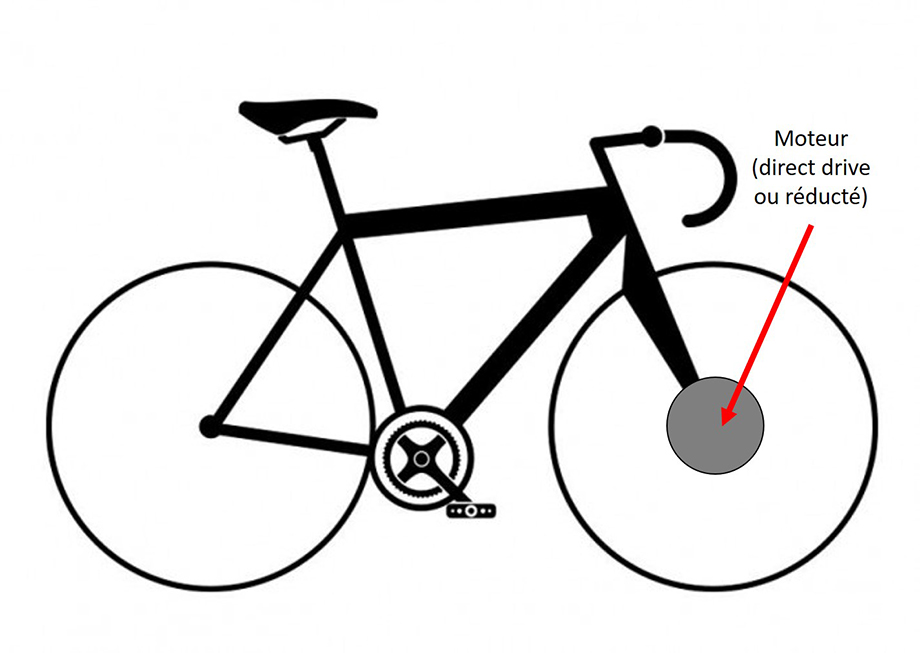

These 2 engines are installed on a vehicle in the same way. In most cases, they are used for the bicycle so let's take as an example a mounting on this means of transport (diagram below).

|  |

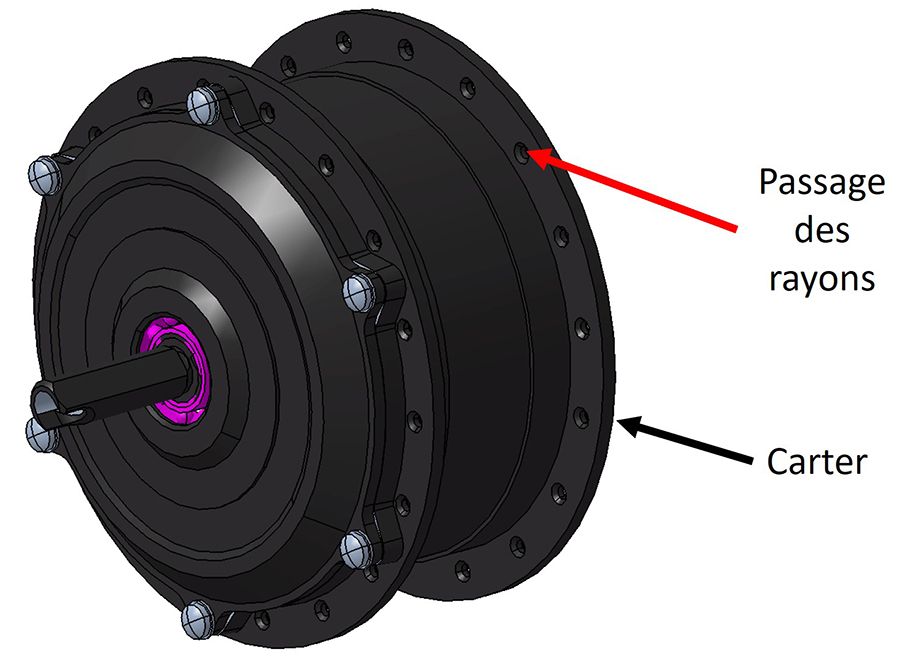

These hub motors have the option of being installed on the rear wheel or on the front wheel. Whether direct drive or reduced, the wheel motor radiates the same way on the rim of the bicycle.

Now that we have seen the principle of mounting a wheel motor, let's go into more detail on the characteristics of these 2 motors.

Direct drive brushless motor

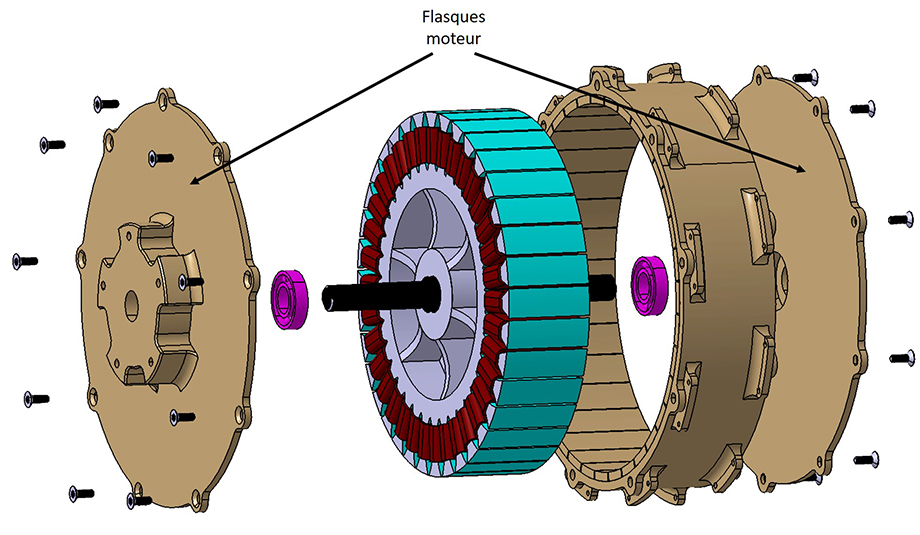

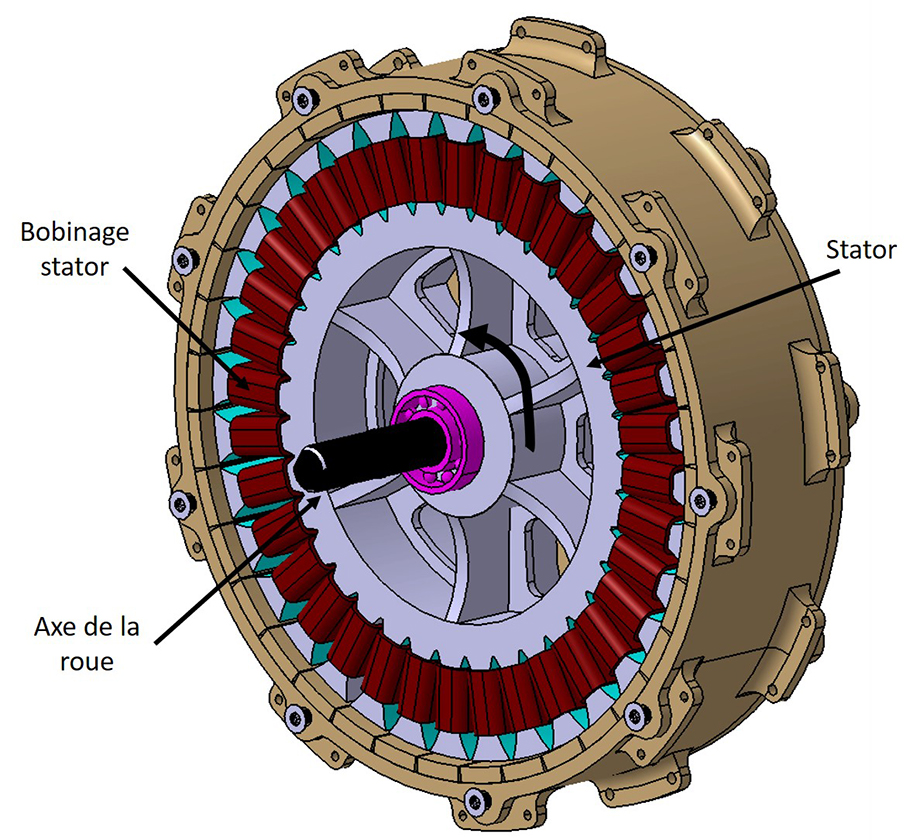

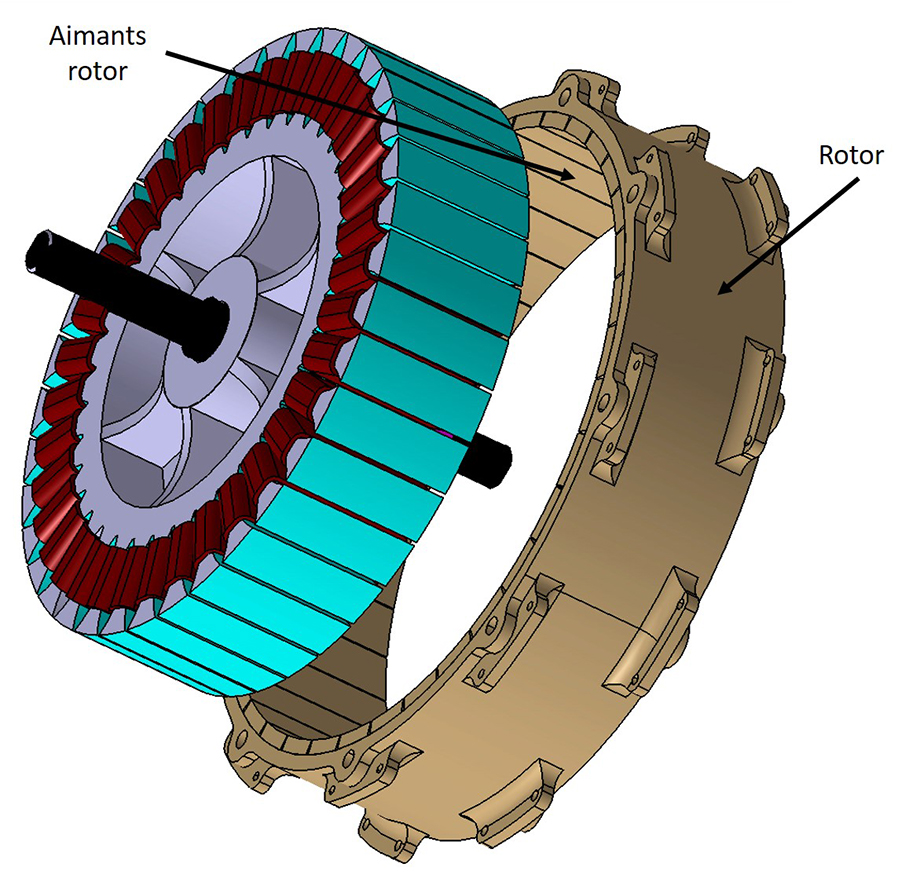

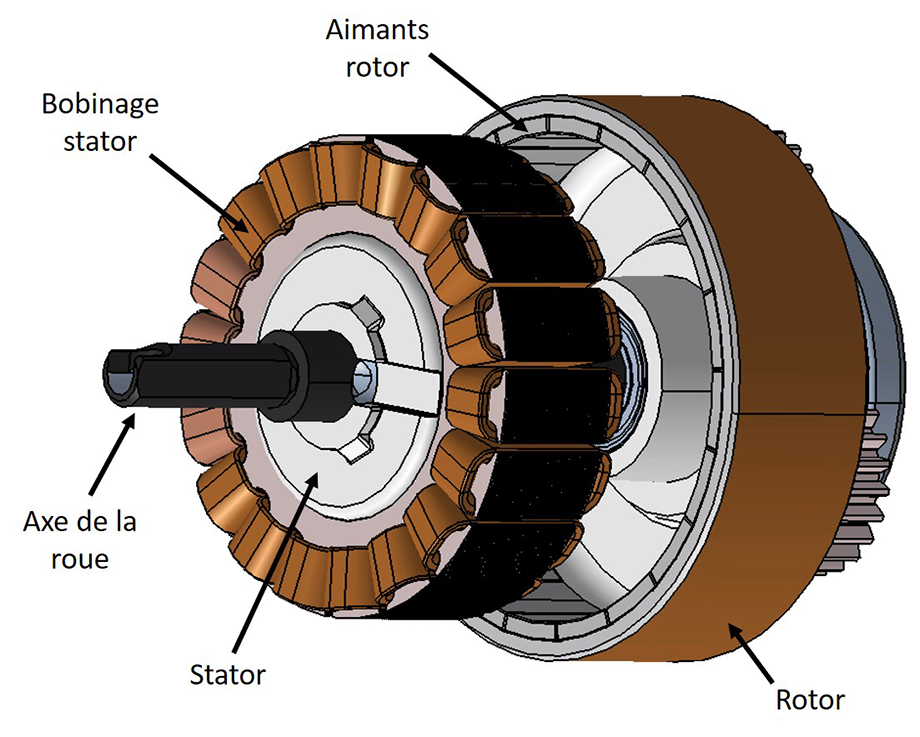

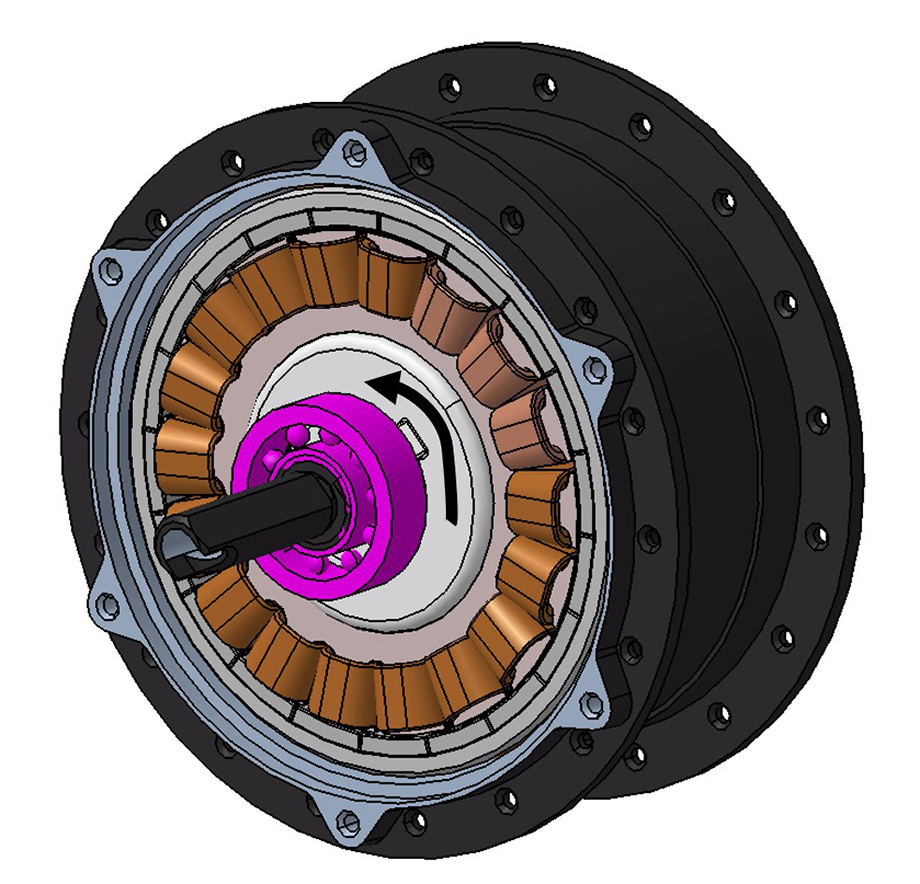

| These current variations in the winding will continually modify the polarity of the poles of the stator which will cause electromagnetic forces which will make the rotor turn via its magnets and therefore the wheel of the bicycle. |  |

| As its name suggests, the brushless direct drive motor is a motor that sends the power of its rotor directly back to the wheel of the bike, without going through gears. The 3 motor phases, coming from the controller, supply the stator winding with alternating current. |

| The motor flanges are then screwed on each side. |

|

Advantages/Disadvantages of the Direct Drive motor compared to the reduction gear

+ :

| – :

|

Reduced type brushless motor

|  |

|  |

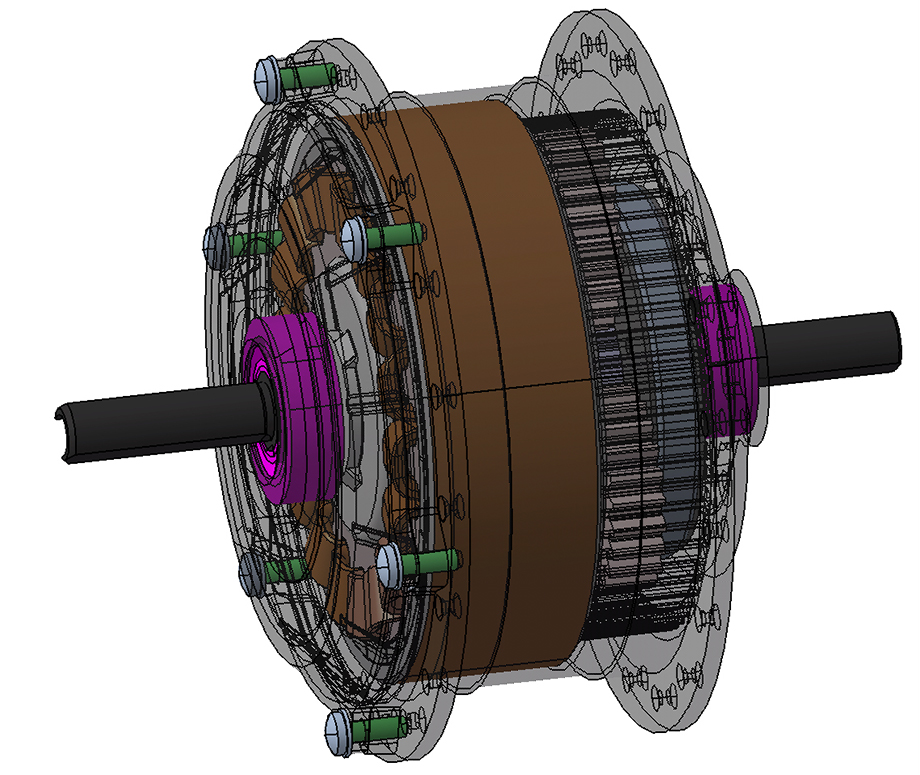

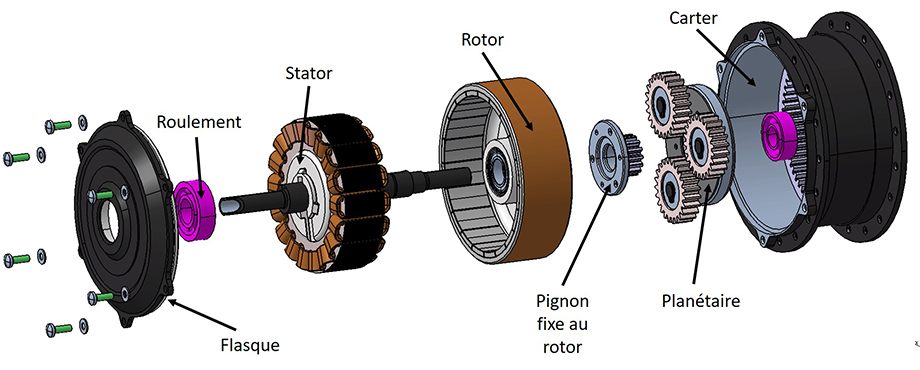

The reduced motor, on the other hand, has a planetary gear to turn the crankcase, and therefore the wheel. This solution makes it possible, for a smaller motor and therefore with weaker electromagnetic forces, to multiply its rotor output power in order to have a much higher motor power. For the 250W motor sold from OZO, the reduction ratio is 1: 4.4. For all other OZO reduction motors (power> 250W), the ratio is 1: 5.

The rotation of the rotor by the stator works exactly on the same principle as for the direct drive motor.

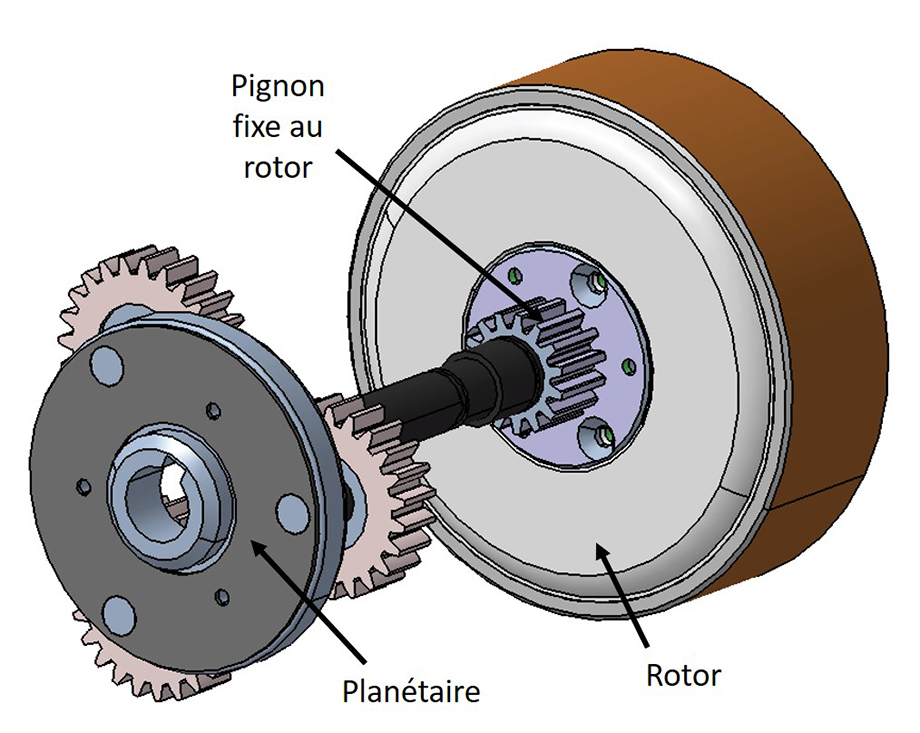

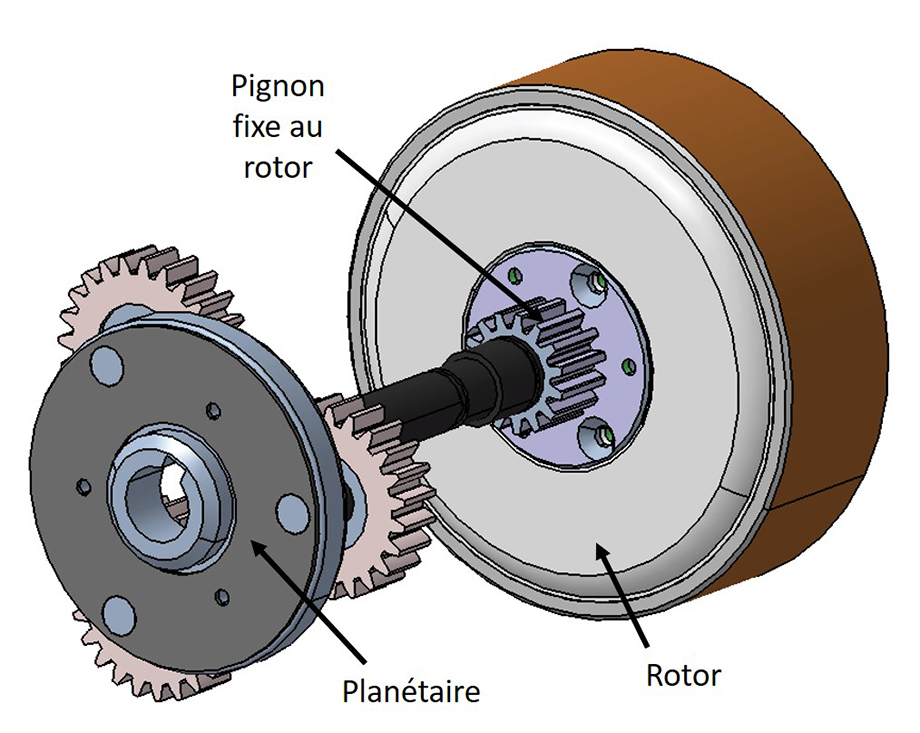

So first, the stator, supplied with alternating current, spins the rotor. Then, a small pinion fixed to the rotor comes to put the planetary in rotation (diagram below).

|  |

| Puis le planétaire vient mettre en rotation le carter moteur, et donc la roue, via une denture intérieure intégrée dans le carter. La vue éclatée du moteur réducté vous permettra d’y voir plus clair. |

Advantages/Disadvantages of the Direct Drive motor compared to the reduction gear

Les + :

| Les – :

|

Conclusion

Now that you can see more clearly about these 2 engines, you are able to understand that these 2 engines are complementary and that your choice will depend on your type of use.