200mm electric wheel motor for industrial and logistics trucks for disc brake

We offer a 200 mm diameter brushless electric wheel motor specially designed for the electrification of industrial forklifts, as well as any other rolling stock used in intralogistics or on a production site. This system provides electric assistance to forklift trucks, reducing fatigue and improving operator comfort.

Our motors are ideally suited to a wide range of applications, including the agri-food sector (for push-pullers, refrigerated trucks, kitting and racks), the industrial sector (for rolling bases, industrial trucks, racks and production machines) and the logistics sector (for picking trucks).

With this electrification solution, we aim to facilitate and optimize daily operations in these different fields

Power:750W / Centre distance: 169mm

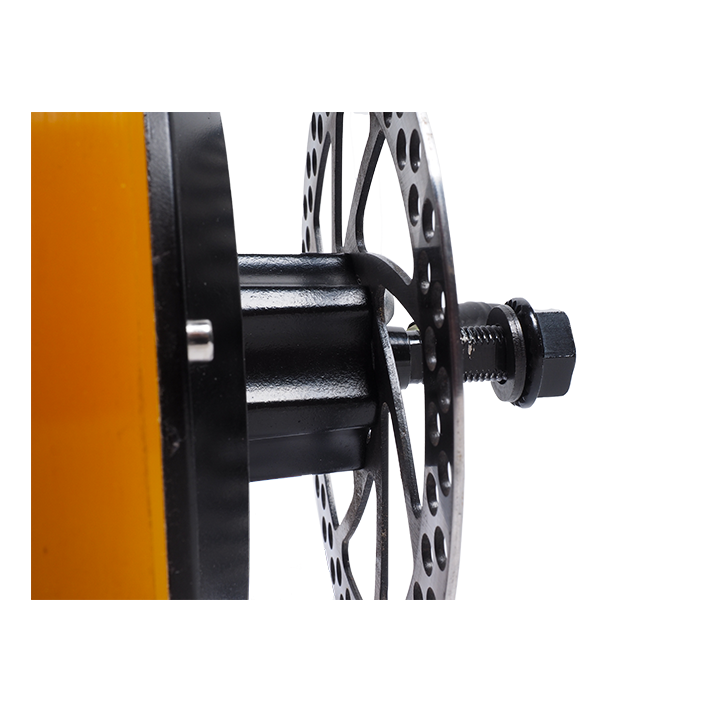

Sold without disc

We've designed this electric drive wheel specifically to electrify all industrial rolling bases used in materials handling or logistics.

Its main objective is to facilitate the electrification of your logistics or production trucks, in order to reduce work fatigue for your operators while complying with CSR standards.

With a continuous power output of 750W, this drive wheel can motorize a wide range of equipment, including push-pulls, sideboards, picking carts, industrial racks and even hospital beds.

We supply a 140mm cable with this electric drive wheel. Its 50mm-wide polyurethane tread offers excellent grip on all types of industrial floor, and eliminates any risk of punctures. The outer diameter of the tread is 200mm.

The brushless motor operates in direct drive, guaranteeing totally silent operation when used with our programmable OZO 25A controller. What's more, a built-in temperature sensor protects the motor from overheating under heavy load.

Our programmable controller allows advanced customization of motor parameters to suit your needs, such as feed speed, torque, response time, acceleration, maximum voltage, etc.

You'll benefit from total control, with the ability to move the carriage forward or backward, activate or deactivate the motor, and more.

Thanks to our controller's vector technology, these machines can be operated without generating noise pollution.

This motorization is perfectly in line with the new CSR (Corporate Social Responsibility) standards for reducing work fatigue and occupational risks.

By electrifying your work tools, such as hospital beds, trolleys, push-pullers or other handling and picking carts, you can quickly and easily reduce these risks.

This solution is ideal for rapid compliance with CSR standards, for factories 4.0 and for intralogistics needs.

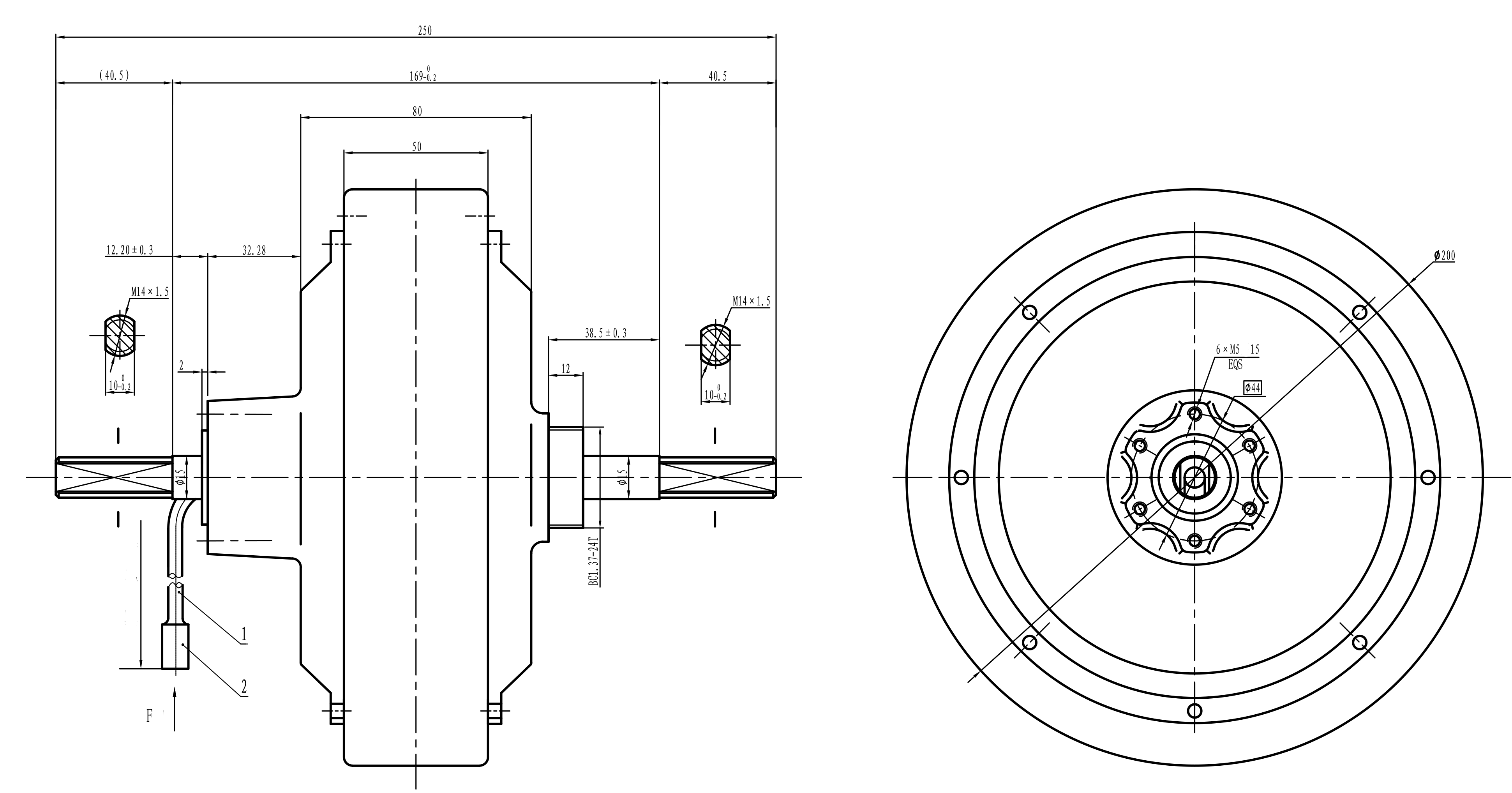

2D plan of the motor:

| Guarantee | 2 ans |

| Intensité max | 23A |

| Couple max en 36V | 52N.m |

| Tension | 36V |

| poids en 26 pouces | 6,5kg |

| Couple max en 48V | 52N.m |

| Etanchéité | IP67 |

| Rendement | 85% |

| Technologie moteur | Brushless Direct Current Motor (BLDC Motor) |

| Puissance max | 750W |

| Rendement max | 90% |

| Motor Kv (RPM / V) | 4.8 RPM / Volt |

| Hall sensors | Yes |

| Ipmax | 20A |

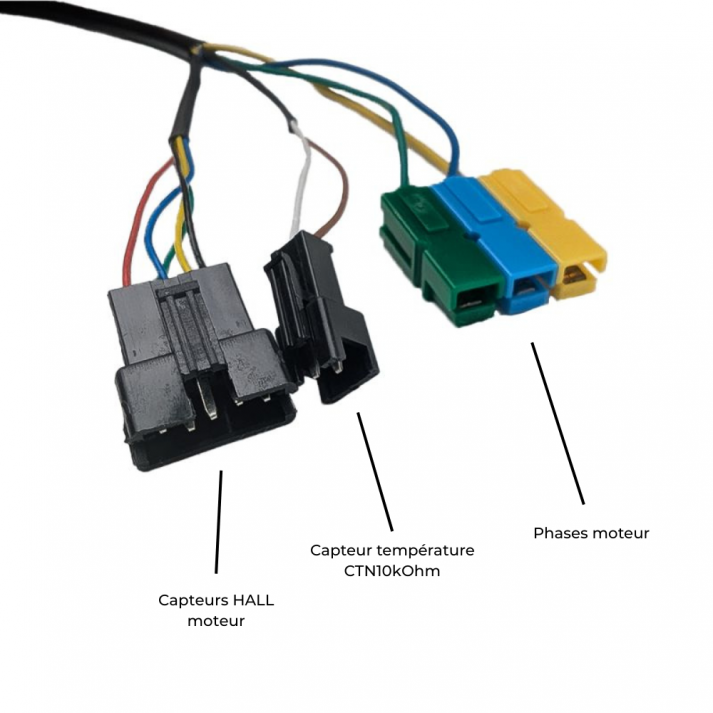

| connecteur moteur | Anderson PP30 pour les phases, JST pour les capteurs et la sonde de température |

| Nombre d'aimants | 20 |

| Vitesse max | 6km/h |

| Tread width | 50mm |

| Cable lenght | 1500mm |

| couple nominal | 20 N.m |

| voltage range | 24V - 36V - 48V |

| Shaft diameter | 14x10 |

| Codeur | NON |

| Capteurs Hall | OUI |