WHAT ARE THE DIFFERENT AVAILABLE WHEEL MOTORS?

Whether you are a novice or a passionate, it is always interesting to understand how the equipment of your E-Bike works. This can help to identify a breakdown more simply or simply to enrich your knowledge in a booming environment.

Today, the wheel motor, also called a hub motor, has become a simple and essential way to electrify a large number of light vehicles (bicycle, motorcycle, scooter, scooter, etc.). Indeed, this solution, fixed directly to the frame, does not require the readaptation of the transmission. This is a "brushless" motor, meaning brushless motors.

There are 2 types of wheel motors: the direct drive motor and the Gear reducted motor

In this article, we will focus on the different wheel motors that we offer.

FRONT WHEEL MOTOR AND REAR WHEEL MOTOR

paragraph

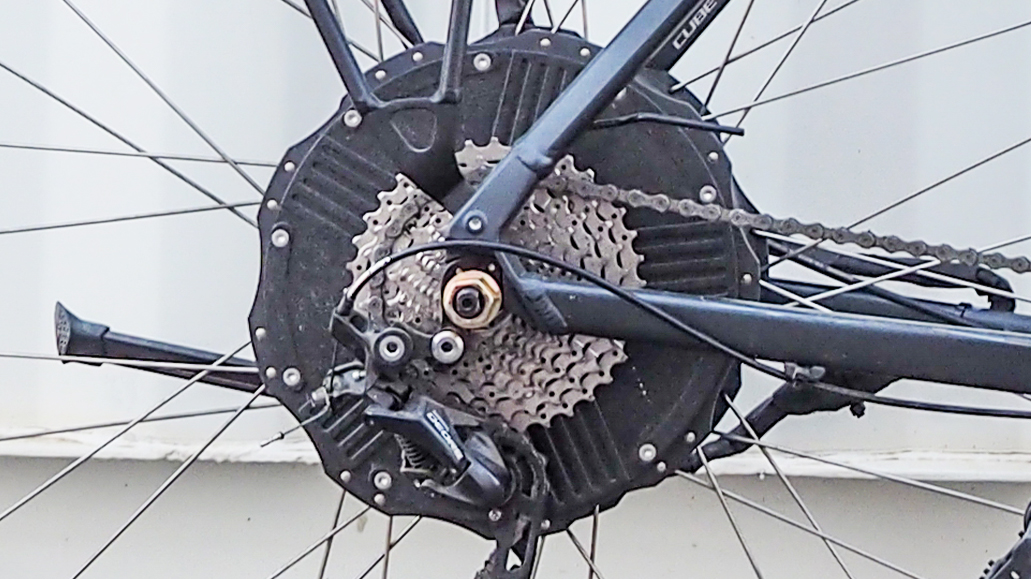

THE REAR WHEEL MOTOR

Better grip on slippery surfaces

Compatible with all practices

General purpose

Integrated speed hub not compatible

Coaster brake not compatible

Not compatible with 12-Speed cassettes

THE FRONT WHEEL MOTOR

Compatible with rear hubs with integrated speeds (Nexus, NuVinci...)

Compatible with coaster brakes.

Less grip on slippery surfaces

Not suitable for MTB

Not recommended on Carbon forks.

THE ESSENTIAL OZO MOTORS

BOBBER MOTOR (FRONT AND REAR)

The BOBBER motor is the ideal companion for those who want efficient assistance but do not want to compromise on the weight carried. It delivers a torque of 40N.m.

Equipped with a cassette holder compatible with all Shimano and Sram 7, 8, 9, and 10-speed cassettes.

FREERIDER MOTOR

The Freerider motor is a motor originally designed for the electric mountain bike: Enduro, Freeride. It is equipped with a cassette holder compatible with Shimano and Sram 9 and 10-speed cassettes.

Weight 4kg

Power: 500W at 36V and 750W at 48V

THROUGH AXLE MOTOR

The HORNET electric motor is the ideal companion for those who want efficient assistance but do not want to compromise on the weight carried.

The Hornet motor is a 36V 250W electric wheel motor specially designed for bicycles with a 12x142mm through axle.

DONKEY MOTOR

Big brother of the Touring kit but with a more robust motor offering 55N.m of torque, it is suitable for pilots weighing more than 80Kg or those who wish to tow a trailer or carry heavy loads. This kit is suitable for Biporteurs and cargo bikes with a 20'' front wheel.

BROMPTON MOTOR

Specially developed for the foldable bike Brompton, this electric wheel is to be installed in place of the original wheel (16 inches, 3/8 spacing 75mm).

ROLLER BRAKE MOTOR

The front wheel ROLLER motor is a 250W electric hub motor of the reduced type that delivers a torque of 40N.m. This motor is intended for ROLLER BRAKE brakes that are generally found on Dutch bikes (Gazelle, Batavus, Amsterdamer...).

DIRECT DRIVE MOTOR

We offer the DD27 cargo motor in a version dedicated to mid-heavy load transport applications: tricycle, trike, bike taxi, cargo bike, wheelbarrow, scooter, tandem, special, industrial, agricultural machines... If you need a motor for heavier loads, we recommend the DD35 transport motor.

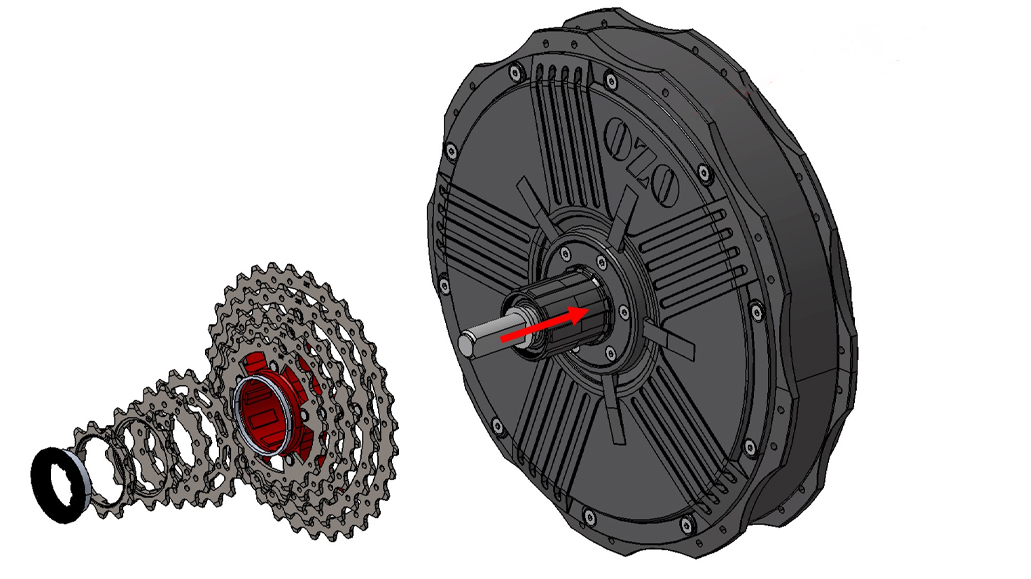

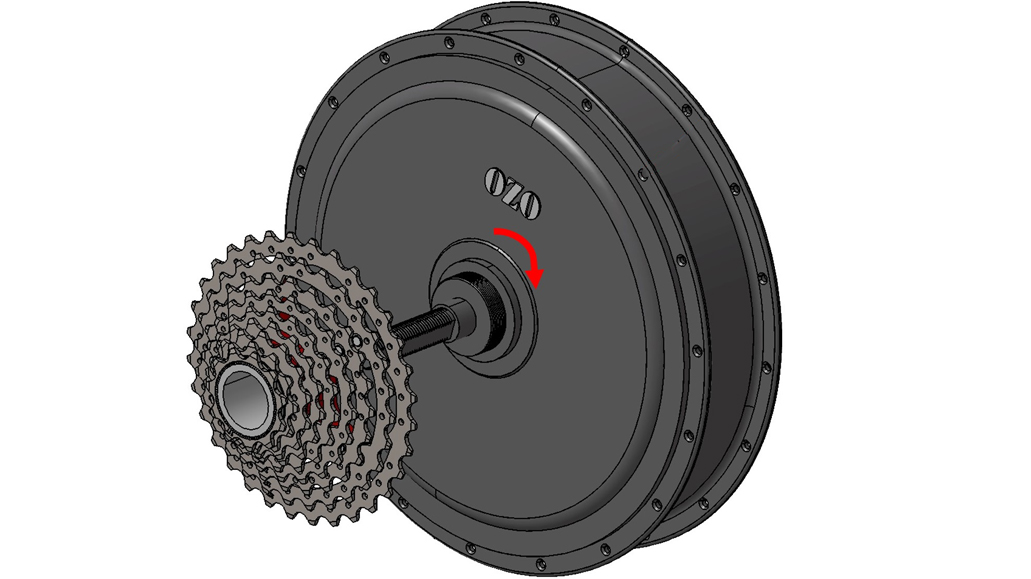

CASSETTE OR FREEWHEEL?

A freewheel and a cassette have exactly the same role and shape. So what makes them different? It's simply their attachment to the wheel. The freewheel screws on while the cassette inserts into a groove. So it's impossible to mount a cassette on a wheel meant to accommodate a freewheel and vice versa. Let's delve a little deeper.

The cassette body slides onto a freewheel with integrated splines on the hub of the wheel or motor if you have a hub motor. The sprockets are not linked together like the freewheel, they are threaded on one by one and are then held by a nut screwed onto the end. Changing a sprocket is therefore simpler. However, cassette manufacturers do not all have the same spline standards. Compatibility is less obvious than for the freewheel.

The freewheel body screws onto the hub of the wheel or motor if you have a hub motor. It is an assembly of sprockets that form a single block with an integrated system inside that allows you to stop pedaling without stopping the wheel.

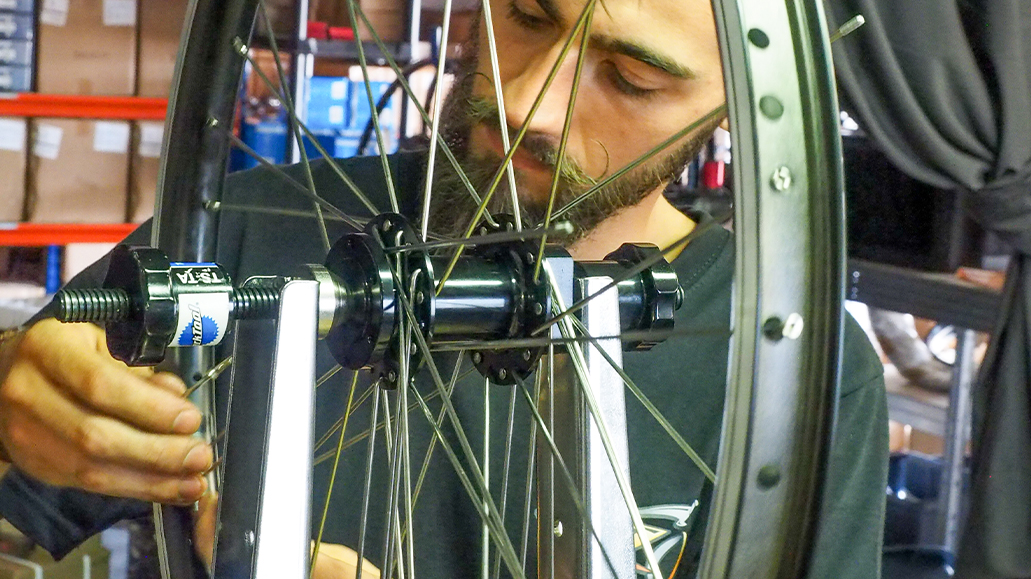

WHEEL SPOKING

All our wheels are carefully spoked in our workshop by enthusiasts: spoke tension, centering, truing, and runout are all checked before shipping. The 36 spokes are made of 2.3mm diameter stainless steel, made in France.

We also offer a custom spoking service for our customers.

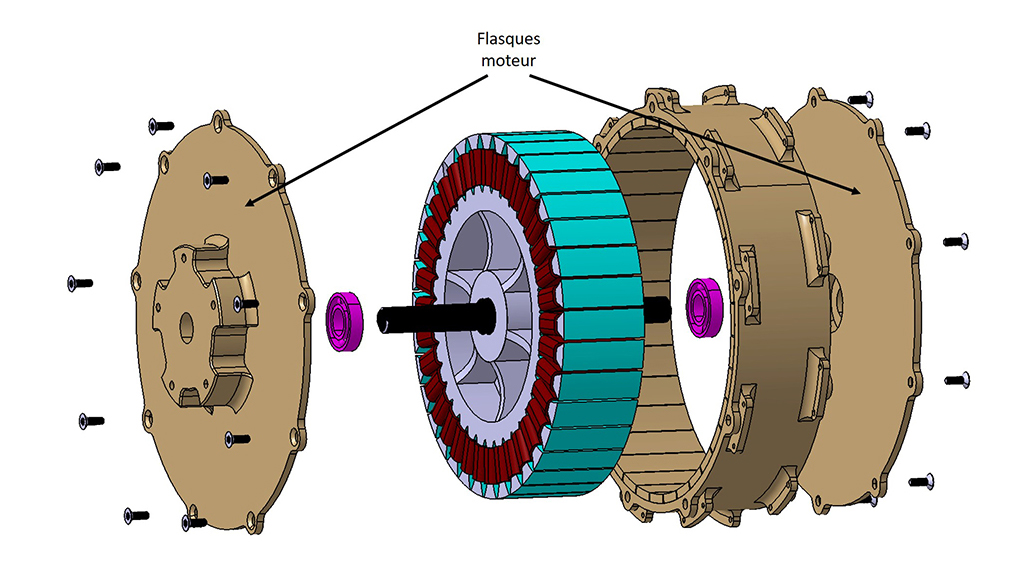

THE TWO WHEEL MOTOR TECHNOLOGIES, DIRECT DRIVE MOTOR AND GEAR REDUCTED MOTOR

THE DIRECT DRIVE MOTOR

simpler design

Fewer parts mean fewer breakdowns.

Allows for regenerative braking

Lower price.

totally silent.

The diameter of the direct drive motor is larger.

The mass is higher (on average 1.5kg more).

When pedaling manually, the motor slightly brakes because it does not have an internal freewheel to disengage it when it is not powered.

THE GEAR REDUCTED MOTOR

The motor is smaller and lighter. This motor uses gears to increase available torque.

The internal freewheel allows the motor to be completely disengaged when not powered. The motor does not brake during manual pedaling.

Regeneration is not possible.

The gears and freewheel are wearing parts that will need to be replaced every 15,000km or so.

higher price because there are more parts and it is therefore more expensive to produce..

The Direct Drive Motor : As its name suggests, the direct drive brushless motor is a motor that directly transfers the power of its rotor to the bike wheel, without going through gears. Very simple in design and manufacturing, the direct drive motor is cheaper than the reduced motor and its lifespan is significant because there are few moving parts in this motor.

The gear reducted motor : The reduced motor has an epicyclic gear train (planetary gears) which increases the motor torque by a factor of 4 to 5 depending on the motor model. This solution allows achieving the same torque level on a lighter and smaller motor. For the 250W motor sold at OZO, the reduction ratio is 1:4.4. For all other OZO reduced motors (power > 250W), the ratio is 1:5.

The rotation of the rotor by the stator works exactly on the same principle as for the direct drive motor: Both are brushless motors.