Freeride kit 750W rear wheel with 48V frame battery

The undeniable reference! A pioneer in mountain bike kits since 2010, the OZO Freeride kit incorporates all the improvements one would expect from equipment designed for intensive use in mountain biking. Featuring a reinforced motor and rim, waterproof connectors, a color display, nine assistance modes, and optimized mapping, this kit is ideal for tackling the most extreme conditions.

The 'FREERIDE' wheel kit was designed to push boundaries and expand your horizons. Over the years, it has become the benchmark for those seeking unrivaled efficiency and reliability on their electric mountain bike.

Contenu de ce pack:

Freerider rear hub cassette ebikes motor 500W 750W |

wheelbuilding on French Mach1 double wall rim with 2.3 mm stainless steel spokes |

Display for Bafang protocol |

22A Controller integrated in holder for frame battery Quantité : 1 98,10 € |

Pedal sensor adapted to your bike |

Main wiring harness for 15A and 22A OZO controller BFG |

Torque arm adapted to your bike Quantité : 1 25,00 € |

Rallonge moteur 9 PINS 110cm |

48V Lithium Battery frame 670Wh to 1000Wh |

48V 2A , 4A or 5A charger for Lithium LiMn batteries Quantité : 1 39,90 € |

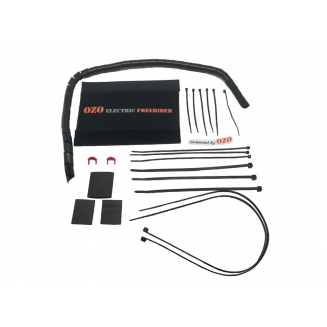

Mounting pack for electric kit Quantité : 1 Gratuit |

THE ADVANTAGES OF THE FREERIDE 48V 750W KIT

The « FREERIDE » wheel kit was designed to push limits and expand your playground. Over the years, it has become the benchmark for those seeking unrivaled efficiency and reliability on their electric mountain bikes.

The Freeride kit is equipped with a 22A setup, It's a more advanced and technical version compared to the Enduro kit.. The 22A controller enables management of a more comprehensive and technically advanced range of accessories. This kit is suitable for advanced users with high demands.

Find a selection of necessary accessories for making an electric motorized wheel: puncture-proof tires, inner tubes, brake discs and cassettes. Don't forget the tools essential for your wheel motor.

SPEED

45 km/h

TECHNOLOGY

9 assistance modes, color display, automatic disengagement.

FOR WHOM ?

Those who want maximum torque and speed.

SINCE 2010

OZO has been marketing and improving this kit since 2010.

COMPATIBILITY

Compatible with 90% of bikes.

VERSATILITY

No limits! The most powerful in the range.

COMPATIBILITY

Our kits are adaptable to 90% of bikes on the market.Our 750W rear wheel motor kit is compatible with mountain biking, trikes, and tandems.

Ensure easily that your bike is ready to be transformed into an electric bike for smoother and more enjoyable rides.

Indeed, whether it's a front-wheel motor, a rear-wheel motor, or a mid-drive motor, various measures need to be taken.

KIT CONTENTS

A MOTORIZED WHEEL

A hand-spoked wheel with a 250W motor, and rims and spokes made in France.

A DISPLAY

The control screen displaying battery life, speed, and distance.

A BATTERY

To be chosen based on the desired range.

AUTONOMIE

With the 750W mid-drive motor kit, we offer 2 different types of Lithium batteries to choose from based on the range you desire.

The 670Wh frame battery, the most versatile in our range, with lock and offering a range of up to 130km.

The 1000Wh frame battery, perfect for long-distance adventures, providing up to 170km of range.

SPARE PARTS AND REPAIRS

Repair your kit at OZO

OZO considers repairability during the product design phase and provides spare parts so you can maintain your electric bike motor kit yourself.

You will also find all our tutorials to guide you step by step in maintaining your electric bike.

.

ACCESSORIES

The OZO accessories

To complement your kit, OZO offers various accessories,

such as accelerators, chargers, lights, and braking systems.

Discover our accessoriesASSEMBLY EXAMPLES

| Puissance | 750W |

| Maximum speed | 40 km/h |

| Motor position | Back |

| Batterie | 48V |

| Vitesse (km/h) | 40 |

| Type de vélo | Tandem, Trike couché, VTT |